Years ago, in our previous house, I described how I monitored the return temperatures from our underfloor heating system Raspberry PI and OneWire temperature sensors.

Here I will describe the supply side of our current Hydronic Heating System. The next blog-post will describe the consumer side as it is now.

The underfloor heating supply temperature varies between 22 and 40 Celcius (72 – 104 Fahrenheit) the colder it is, the warmer the floor needs to be to heat the house.

The simplest way to achieve this is to regulate the boiler temperature directly. We use an HTP Phoenix light duty 80 kBTU/h boiler which is capable of doing this, it can even be connected to an outside temperature sensor, so the floor temperature can be adjusted according to how cold it is outside, it is worth noting that using a low boiler temperature while most economical, will not be enough to heat the Domestic Hot Water (DHW) HTP indirect DHW.

If a single boiler has to supply heat to both the house, and DHW, it has to be run at least 60 C (140 Fahrenheit), to avoid Legionella. A 3-way shunt valve can be used to control the temperature of the water going into the hydronic underfloor heating.

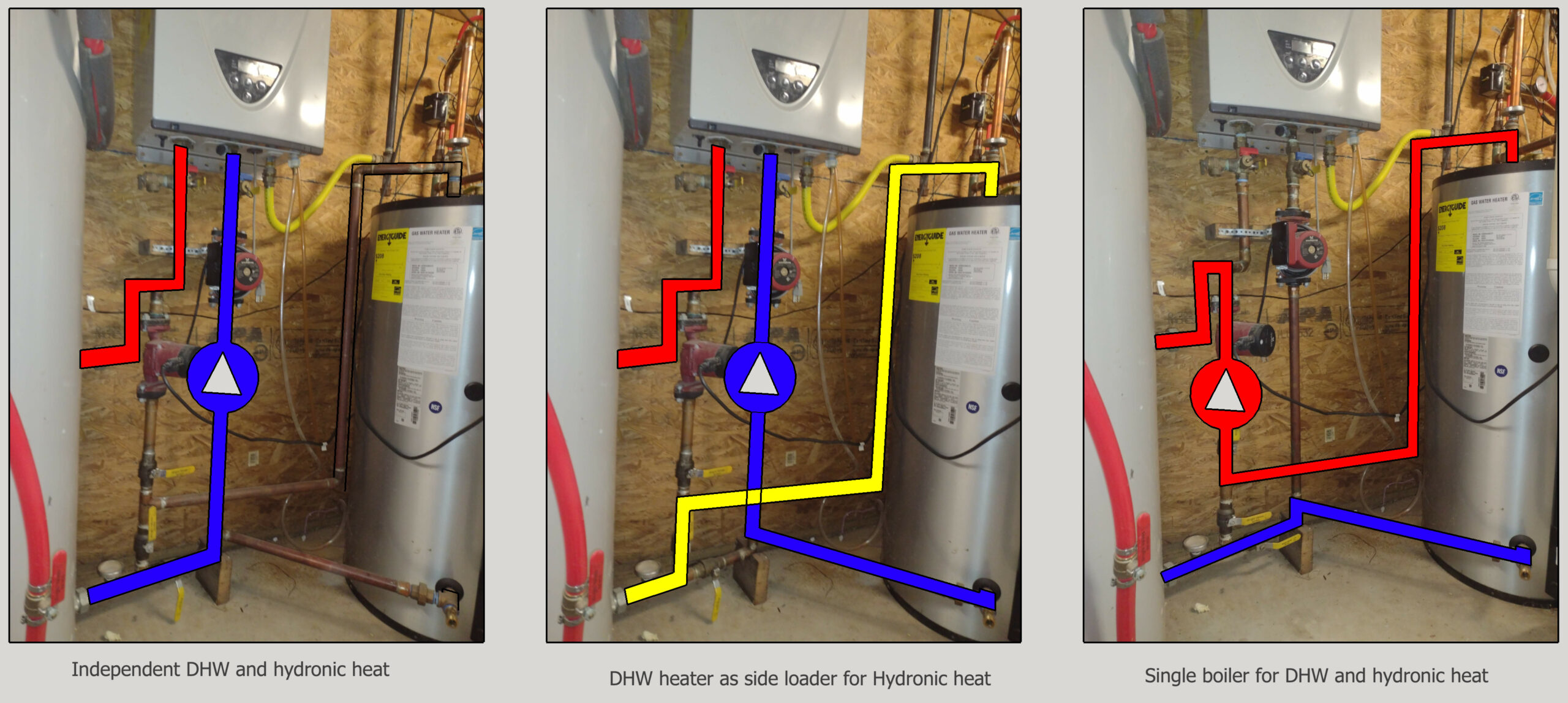

The simplest setup is to have 2 independent systems, the above-mentioned boiler to supply heat to the house and f.ex a Takagi 199 kBTU/h tankless water heater for DHW, and this is exactly the setup we have.

It turned out that the 80 kBTU boiler is not enough to heat the house on the coldest days, when a floor temperature of more than 35 C (95 Fahrenheit) is needed, the boiler cannot keep up. at the same time, we have 199 kBTU/h heating capacity for the DHW, which is only used when someone is taking a shower.

Tankless water heaters can be a little annoying since they are cold when not used, hence it takes a few seconds before the water will be heated up when turning on a hotwater tap. As described in Why Add a Tank to a Tankless Water Heater? a simple fix is to add a hotwater tank to the setup.

To mitigate these issues our system consists of two tanks, one tank for DHW, and one for the underfloor heating. The system can operate in one of 3 (4) modes, depending on the position of the 3 valves at the bottom of the photo.

- Independent: The Takagi tankless heater takes care of DHW, and the HTP Phoenix takes care of heating the house.

- Dual Boiler mode: The Takagi tankless heater heats DHW, and heats the hydronic tank once the DHW is up to temperature, if required.

- Takagi only mode, Same valve configuration as Dual Boiler mode. The system would still be able to deliver DHW and heat the house, if we could get the Takagi to deliver the 199 kBTU/h promised in the specification.

- HTP Phoenix only mode, The boiler which is also the hydronic tank, is used to supply heat to both DHW and the house

Hence we have a setup where even if one of the Boilers would fail, we could stilll continue with just using rhe remaining boiler. On the very coldes days, the would not be enough to keep the house cosy. We use our Wood Stove to supply most of the heat to the livingroom areas, which is connected open-plan.

In independent mode, The HTP Phoenix would supply heat (at relatively low temperature) directly to the hydronic underfloor heating,. This would be the most efficient setup.

In HTP Phoenix only mode, the boiler has to run at 60 C (140 F), and a Shunt regulator is required to keep the desired floor temperature, Depending on the DHW usage this would also make the floor-temperature more stable in the modes where the Takagi delivers all or some of the heat to the house.

Looking at design now, it is clear that had the system been designed like this from the beginning, a design with only one circulator with the same functionality could be acheived, hind sight is 20/20.

To get a lot of BTU out of a tankless water heater you either need a high flow or a large difference between the input and output temperature from the Takagi. Hence the circulator feeding the Takagi, is a little beefier, than normal.

1 BTU is equivalent to rasing the temperature of 1 lbs water 1 degree Fahrenheit. Raising the temprature of one Gallon of water from 80 to 140 Fahrenheit takes 500 BTU, assuming the pump can deliver 3 gallons/minute this would result in the Takagi producing 90.000 BTU/hour, for higher output a larger pump is required and probably larger pipes, or a higher setPoin temperature.

Controlling the Heat source(s)

Not much is needed to control the heat source(s). Each heat source has a setPoint temperature and the boiler(s) have their own control-system and will try their very best to produce a stream of water at the given setPoint temperature. The setPoint we use is 140 Fahrenheit (60 Celcius), which might have to be increased if the house demands more heat.

You must be logged in to post a comment.